- Spur gears, pinions/pinion shaft

Gear Grinding Wheel

Applications / Workpiece

Advantages of Cubitron II Wheels

- Up to 50% shorter grinding cycle

- Up to 50% less turning

- Up to 2x longer wheel life

- Minimal risk of burning

Gear grinding operations demand exceptional dimensional and contouring accuracy. 3M Cubitron II threaded grinding wheels consistently achieves required tolerances with higher grinding parameter than standard tools. Also despite high contact, virtually no thermal load is created between cubitronII threaded grinding wheels and the workpiece. This practically eliminates the risk of abrasive burning under typical grinding conditions.

Threaded Gear Grinding

Bevel Gear Grinding

Along with worm wheels for continuous gear grinding, our product range includes solutions for discontinuous grinding processes, including:

- Plunge grinding

- Eccentric grinding

- Gear profile grinding

Learn about gear grinding wheel performance:

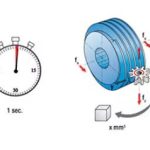

Maximum material removal rate (Qmax) is a useful indicator when establishing performance parameters for a given machine model. Qmax refers to the chip volume in mm3 that can be removed in 1 second, and is calculated as follows:

Q‘w max =

hev: Ground profile height (mm)

nss: RPM of worm wheel

gg: Number of starts on grinding worm

fz max: Max. axial feed rate per revolution of gear workpiece (mm/rev)

cos β: Cosine of the helix angle of gear

This formula will help establish your maximum removal rate. Keep in mind that it is important to consider other performance parameters like average chip thickness.

To learn more about key gear grinding calculations and formulas, contact us today and request your free copy of our Gear Grinding Booklet.